Sticking to Sustainability: How modifying the tape in research labs can help cut plastic waste.

Lab Rats was a design research focused project tackling the plastic waste produced by research facilities at the level of both the recyclers and the lab level.

Research labs produce 12 billion pounds of plastic waste a year. Our challenge was to find a way to reduce this number while working within the established system of the research community.

Lab Rats desktop application to help create a database for plastic inventory in use in the lab.

Lab Rats label maker UI with pre-loaded experiement protocols and custom experiment protocols.

Example of the labels generated and the information encoded in the QR code.

Robotic arm (Harvard Adv Robotics Lab) coded by Shifandi Sun to recognise and sort plastic items based on the QR reading.

Project Details

3 months (October 2023 - December 2023)

Samyukhta Sam ‘24

Shifanfi Sun ‘24

Sunny Satpathy ‘24

My Roles

Interviews

Research and Testing

Physical Prototyping

UI Development

Tools

Figma

Miro

Autodesk Maya

Autodesk Fusion 360

Why is recycling plastics from research facilities so challenging? Two words: SAFETY PROTOCOLS.

Research labs use various single-use plastics, primarily grades 1, 2, and 5. When exposed to toxic chemicals, these plastics are marked as biohazards and excluded from recycling.

However, many can be sterilized and safely recycled but are often mislabeled. Our goal is to identify and redirect these plastics into the recycling stream.

So…what is happening inside a research lab?

Lab Rats started with this very question asked to 8 professionals working at research facilities, recycling facilities and in the artificial intelligence and robotics fields.

2 Software Engineers (Gladstone Research Labs, Microsoft)

4 Researchers (Pathologist, Biomedical Engineering PhD Candidate, Biomedical Engineering Student)

2 Recyclers (GreenLabs Recycling, RE-Plastic Team @ Brown School of Engineering)

Safety of the person handling the trash takes precedence to avoid accidents.

Most research labs recycle paper and cardboard, but plastics are often discarded as biohazards even if they haven’t made contact with toxic chemicals.

“They care about the environment, (but) safety of the custodians trumps the environment.”

Everything has to be sterile

During an experiment things aren’t allowed to accumulate and are tossed immediately after use.

Time is a huge constraint

Time and results are of the essence. Extra steps = More time, which hurts efficiency and productivity.

“No one wants to do research with reused materials. It can mess up results”

Tasks are repetitive and require high accuracy

The work is meticulous with many things to keep track of, every step is important and you cannot lose focus.

Lack of labeling and lack of standardization

Lab apparatus often use various types of plastics, including different types for lids and containers, making sorting and identification challenging.

“Big manufacturers don’t trust recycled plastic”

It became clear that building trust is crucial for the project, both among researchers using and disposing of equipment, and recyclers receiving it.

Our insights revealed that expecting researchers to sort plasticware themselves wasn't practical. They prioritize experiment success and throughput over identifying recyclable disposables.

To overcome this challenge, we opted to change our approach...thus, we devised a solution to make

Making a win for lab researchers a win for the environment

I started sketching solutions that would add multiple steps to the researchers already overful list of tasks. Additionally, it was difficult to justify a digital intervention that could just as easily be performed by a phone or a laptop.

Best solutions come from looking at what is already there: our Trojan Horse, Sticky Tape

What if we used the labels scientists use to tag items in the lab to provide all the plastic information recyclers need?

This would integrate into researchers' workflow and help pack relevant details about the plastic’s exposure, aiding the downcycling process at recycling plants.

Designing a smart label maker that seamlessly integrates into a researchers high stress, high pressure environment.

Can we justify a hand-held form or something that would clip on to the various bench shelves present in the space?

Despite exploring fun shapes that would fit the palm of a hand, we went with a classic rectangular shape that could clip on to the shelves at a researcher’s desk. This was done since the product has a UI component requiring researchers to input data and that shape works the best with touchscreen features.

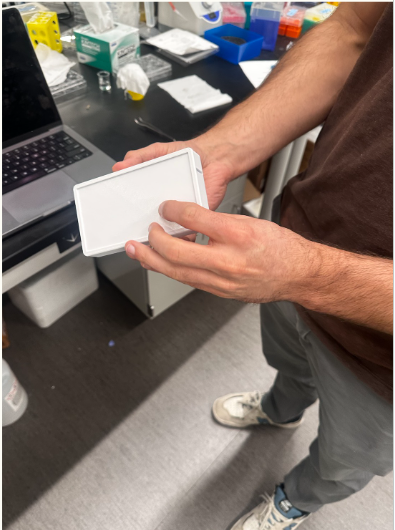

3D renders and 3D print and Alec (person from a the Brown School of Engineering Shukla Labs) holding it

Here is how a label maker can help with plastic sorting at a system level

Researchers select the experiment protocol, and the label maker generates customized labels.

Generated labels include QR codes with plastic type and chemicals used in the experiment info.

Shifandi Sun developed the robotic arm, which scans QR codes to sort plastic by type and color at the recycling facility and the additional information in the QR helps maintain plastic chemical integrity.

Figuring out ways to continue incentivising the use of our label maker in the research lab space…

We took our idea of Lab Rats back to the research lab where we conducted the ethnographic study and identified the next steps for Lab Rats.

Alerting the researcher of the apparatus’ potential to be recycled at the Experiment Protocol or Equipment selection phase to show individual impact.

Figure out ways to make the label application process even faster.

The feature for keeping track of apparatus stock in the lab is useful and could be integrated with existing equipment ordering systems.